Dmitry, when you founded Atola 20 years ago, did you envision where the company would end up by 2023?

Back in 2003, Atola began with an ambition to create revolutionary technology rather than business. Having worked in the data recovery industry for over a decade, I knew I could automate the otherwise mundane and cumbersome process and make data recovery accessible for anyone.

The vision of what we could achieve as a business with this technology transformed over the years. Essentially, we followed our customers every step of the way. When our data recovery solutions suddenly became in high demand in the forensic field, we met our new customers to understand their needs and create products that combined our existing technology with the features required for their use cases.

What I did envision for the company and now can say has been accomplished is keeping a relatively small team of highly skilled people. Hiring the right people and keeping a high level of trust in each other is an essential part of our success. The development of innovative products like Atola TaskForce was made possible by this teamwork plus the agency we maintained to be flexible when setting our priorities and quickly implement our ideas.

Vitaliy, you have been heading this team of engineers for 15 years now. What milestones do you look back on that define Atola the way it is today?

Back in 2008, I joined Atola to help develop the 2nd generation of Atola Insight hardware imager. It’s remarkable to see our evolution from a small team of five in 2008 to a dynamic group of around 30 today. Our journey, deeply rooted in digital forensics and data recovery, has been marked by a consistent focus on innovation, UX, and product development. As we are extremely product-focused, I would like to highlight our product launches as key milestones:

• 2009 – Atola Insight with DiskSense Ethernet unit

• 2010 – Atola Bandura

• 2012 – Atola Disk Recycler

• 2014 – Atola Insight Forensic

• 2018 – Atola TaskForce

• 2022 – Atola Insight Forensic with DiskSense 2 unit

• 2023 – Atola TaskForce 2

This list consists entirely of our hardware devices of various flavors. Software comes and goes, hardware is forever! 🙂

Each of these devices and the user experience we created have collectively shaped the identity of Atola as it stands today – a testament to our team’s expertise and unwavering commitment to serving the evolving needs of our customers.

Andrew, hardware development is at the core of the top quality that Atola strives to ensure in every product you design and every single unit you assemble. How has the hardware changed and what has your team achieved in the last 17 years since you joined?

The usual beginning of a hardware startup is its founders and early employees operating from their garage, soldering boards, and assembling devices in person. For the most part, Atola was no exception from this image, the only difference was that we soldered and assembled the first batch of 18 DiskSense units on the CEO’s dining table. I wish we had a garage back then, we desperately needed more space for our production efforts!

It took us two years from the initial development to designing the first Atola hardware unit, DiskSense USB. The unit consisted of a single PCB in a metal case. It was connected to a PC and allowed to copy one IDE or SATA HDD at a speed of 30MB/s. Fast forward fifteen years, TaskForce 2, Atola’s new flagship product, allows to operate up to 26 devices connected via just about any mainstream storage interface. The total throughput of the system is a whopping 25TB/s. To achieve such astonishing numbers, we designed the latest system around server hardware, accompanied by 100+ other components, including our custom-designed PCBs. Considering the operating space, connecting 26 disks at once is a tricky engineering problem. A carefully planned drive organizing system involves two pieces of a companion product called Device Rack. The whole system is designed to be installed into a standard 19” rack, altogether this allows you to operate 26 disks simultaneously, on a footprint of about 4 square feet of floor space.

Speaking of our hardware people, we are a tightly-knit team of 5 professionals who stand behind all Atola hardware products. Each of us has a range of skills, and together we cover all stages of a product cycle: from developing a new device concept into a prototype to putting the boxed product on the shelf of our warehouse in Canada. We do everything related to design and assembly in-house – electronic design, mechanical design, component selection and sourcing, device assembly, testing, and packing. Only the production of PCBs and metal cases is outsourced to contractors.

The key values of the Atola hardware team are product reliability, simplicity, and an appealing product design. It is our pleasure to deliver a near-perfect product to our customers, we stand behind each piece of equipment that Atola delivers to customers. After all, these devices help digital investigators to make the world a safer place, day by day, and we are proud to be a part of this process.

John, around the time you joined Atola 11 years ago, the company pivoted from data recovery to the digital forensics industry. How have Atola products impacted the work of your customers and how does the business evolve today?

Yes, when I joined Atola we were still a data recovery technology provider. In a very early conversation with our Co-Founder and CEO Dmitry, he mentioned that he felt the data recovery marketplace was contracting and that Atola’s systems would reach a kind of saturation within just a few years. Well, not exactly what a brand new Director of Sales and Business Development wants to hear, but of course folks in my profession thirst for these kinds of challenges. I was beginning to really understand what a rock-solid technology we had when Dmitry also mentioned that some of the last few shipments had gone to military and law enforcement agencies. He didn’t know exactly what they were doing with them, but he wondered if there might be something to that. His hunch was correct as they usually are! I immediately made it my mission to arrange and facilitate the meetings and conversations that would provide the catalyst for Dmitry, Vitaliy and Andrew to be able to pivot our technology focus to the digital forensics marketplace and forensic imaging.

As our original forensic imager, Insight Forensic’s combined attributes of automatic bad drive evidence retrieval and super reliable high speeds on good drives were enough to firmly establish our technology leadership. It had a huge impact on our user’s results! No longer did a broken or even a dead drive mean they could not get the crucial evidence they were seeking. Customers were reporting that even if a drive appeared dead to all other technology, their experience made them feel they had a least a 50% chance of obtaining the evidence with Insight. We have heard so many great stories over the years of how Atola’s technology was the only way to retrieve the evidence that provided the “smoking gun”!

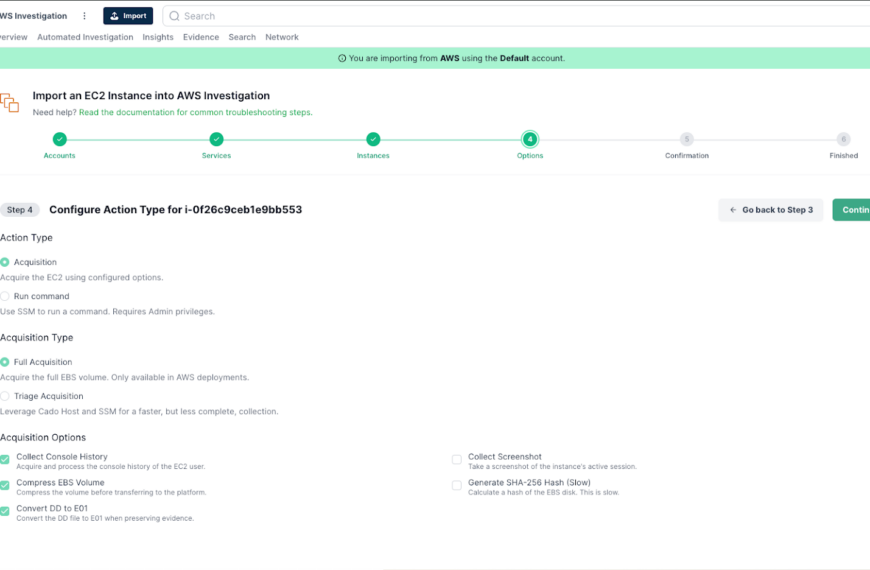

The next big leap for Atola’s technology came after so many customers were reporting not just increased caseloads, but even their average cases had multiple drives of increasingly higher capacity to image. In addition to the bad drive capability and high speeds, they needed an imager that could image more than one drive at a time by more than one user at a time. Again, this vital feedback that we very clearly heard, drove our amazing technical team to create TaskForce, a multi-session (12+) imager for multiple simultaneous users. To add even more capability for high-speed and automated evidence acquisition, a Web API was created that allows TaskForce’s integration into automated environments. The most notable use so far is our unique integration of TaskForce with Magnet’s AUTOMATE.

TaskForce means that many cases at a time can have their drives imaging automatically allowing more time and energy for other parts of the investigation.

The development of our latest offering, TaskForce 2, builds on the success of TF1 and adds even more ports and is rack-mountable with optional Device Racks for better organization. Most importantly, the new high-speed 4 port M.2 / U.2 NVMe dock supports the use of to 5 such drives when coupled with our Extension module. Both TaskForces also now help investigators save so much time when working with the increasingly common appearance of RAID systems with the RAID Autodetection and reassembly module. Yet again, two features requested by our esteemed users!

Atola’s technology and company will continue to evolve and serve our customers by continuing to carefully listen to their needs through our tech support portal, online presentations, onsite lab meetings, and at our many annual conference booths around the globe. These important conversations with customers and prospects will continue to help us set our development priorities to help our users to be even more successful in their vital work, every day.

Tetyana, the QA team’s work is crucial to the success of Atola products. Tell us how your process is changing to tackle the increasing complexity of both the hardware and the software of Atola TaskForce and Atola Insight Forensic?

Every time we design a new hardware unit, it makes quality assurance about twice as complicated. The time spent preparing, holding meetings, generating test data, and testing itself grows exponentially. Time efficiency is the name of the game: every task requires a thorough risk evaluation, component change and testing process adaptation.

Quality assurance for us is not just about testing but also quality management. To achieve the best outcome, we get involved early on in the design stage: be it hardware, component or functionality development. The QA team works with the software team in different development stages and participates in requirement engineering, market research, UX development, and design.

To be able to routinely test software on huge amounts of test data and to mitigate the human factor, QA automation is applied on a range of components such as UI, API, and integrations. It makes the process more effective and predictable.

In the last few years, my team has adopted the “universal soldier” approach: each of our QA engineers has profound knowledge of all product subsystems and works on tasks of varied complexity: from low-level testing to new file system support checks or UX improvement for old functionality. To eliminate the bus factor, we constantly train and learn.

All these approaches have enabled us to do our work well and ensure the high quality of our products.

Yulia, how has the digital forensics industry changed over the years that you have been a part of Atola and how has it impacted your business, products and marketing strategy? What do you expect to change in the future?

We are observing constant change in this dynamic field. With technological advancements of the last decade came new types of crimes and technical problems but look how much the vendors are doing to deliver the next solution to a problem, be it blockchain, IoT, cloud, or remote investigations!

Arguably the biggest challenge of all, the neverending growth of data volumes is what made us come up with TaskForce imagers in the first place: to be able to process dozens of drives at a time is a game changer! We continued to add more performance boosters to it: the Express mode for zero-click start of imaging, the multi-launch feature for simultaneous task launch on many devices, and of course automation. Like machine learning in evidence analysis, automation was revolutionary for investigators processing large volumes of data. Today, Atola imagers are easily integrated with automation tools, and we are planning to expand the range of Web API commands to enable, for instance, RAID autodetection, reassembly, and imaging initiated via a tool like Magnet AUTOMATE.

We continuously keep track of the RAID types and file systems that become more popular among users and therefore important to investigators. TaskForce’s RAID module will support more of them soon. Next, we will enable access to data in volumes locked with popular encryption methods using a known password. The growing number of NVMe drives is another problem, for which we are looking to provide a flexible solution. These are just a few of the developments reflecting the changing landscape.

As for our marketing strategy, some things have remained the same. We still find in-person meetings with customers and prospects most effective for feedback and sales. We are planning to participate in even more events in 2024 and do other offline activities including training for new and existing customers. Our marketing team grew substantially in 2022, and we have been experimenting with different platforms to find the best communication channels to reach the investigators who need our imagers’ capabilities. We have continued to expand the knowledge base about our products and technology through publications on our website, Forensic Focus, social media, YouTube, etc.

As for the future of digital forensics, we will inadvertently see the need for organizations to keep up with the emerging technology by training staff and investing in solutions that will help in every stage of the investigation process in the world where the only constant is the change itself.